S1 MANUAL

Who said small?

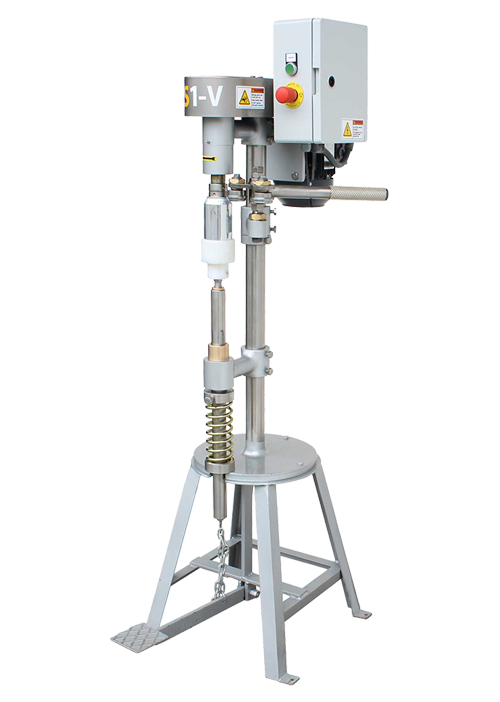

S1 MANUAL CAN SEALER

Take advantage of this versatile manual can seamer and start canning!

FOR START-UPS

SIMPLE

VERSATILE

LOW PRICE

QUALITY SEAM

The JK Somme S1 is a strongly built simple construction and totally manual can sealer – round can closer, that will handle the full range of sanitary sizes, with can diameters from 52 to 222 mm and heights between 20 and 300 mm. Particularly desirable can seamer for:

- Pilot plant canneries

- Starting up canneries

- Expensive canned products, delicatessen, gourmet

- Universities, technical institutes, technical schools

- Laboratories

- Launching new products, new recipes

- Market tests

- Home made canning

A semi manual can seamer for starting in the canning business

Sturdy and reliable it will operate with safety and without requiring any highly qualified engineer for its running and maintenance.

Based on our experience and having in mind ability, can size & fatigue factors one operator could close:

- In 1 hour: 600 cans

- In 2 hours: 1100 cans

- In 3 hours: 1500 cans

For more than 2000 cans closed per day we recommend two S-1 or one Reinerts can seamer.

We manage to obtain the same seaming quality in all the cans, without variations caused by the force applied by the operator

The tooling of the S1 can seamer can be changed in order to close different round can types during one same shift. It only takes a few moments:

- Complete tooling changeover: 5-10 minutes

- Height regulation: 3-5 minutes (without additional parts)

Another key advantage of the S1 manual can sealer is its versatility, having the option of seaming different can diameters & sizes during the same day

Having in mind the low acquisition cost and the daily can productions achieved we can assure that the investment repayment is the fastest of all our can sealers.

JK Somme guarantees buying back the machine once you decide to buy one of our automatic models.

The S1 can seaming machine consists of the following elements:

- Seaming spindle with one rotary seaming chuck

- Manual actuated seaming lever with 2 seaming rolls: 1st and 2nd operation

- Lifter plate actuated by foot pedal with seaming pressure regulated by a spring

- Control panel

- 3-phase or single phase 1 Hp motor

Since 1905, SOMME legendary can seamers have a reputation for being almost indestructible, real “heavy duty”.

- Canned river crab

- Canned snails

- Canned partridge

- Canned bull tail

- Prepared foods

- Duck liver spread – foie gras

- Sauces

- Chatka

- Smoked fish

- Spanish manchego cheese

- Cured loin of pork

- Chorizo

- Asturian stew (beans)

- Lychees

- Guava

- Composite cans

- Chocolates

- Sweets

- Tea

- Pet food

- Bird food

- Medicine

- Talcum powder

- Granulates

- Greases

- Clothes

- Perfumes

- Promotional gifts

- Candles

- Carboard cans

- Bag in Box

- Etc.

ACCEPTED CAN SIZES

- Diameter range: 52 -222 mm

- Height Range: 20 – 300 mm

KEY FEATURES

- Rated speed: Up to 10 cans/minute

- Seaming heads: Single

- Can seaming op.: Rotary can type

- Working mode: Completely manual

- Lubrication: Grease

- Easy maintenance & greasing: Yes

- Tool kit and instruction manual: Yes

PRACTICAL FEATURES

- Estimated tooling changeover: 7 minutes

- Can height changeover: 10 minutes

- Max. recommended production: 2000 cans/day

- Buy-back Guarantee: Yes

DIMENSIONS & CONSUMPTIONS

- Overall dimensions (LxWxH): 1.000 x 1.000 x 1.600 mm

- Net weight: 100 Kg

- Motor: 1 Hp